Here we propose an innovative approach to detect railway track crack as this system detects crack based on image processing. Many image preprocessing steps is used to detect railway track crack. As image is prone to noise. System converts image to grayscale image and uses filtering to remove noise from image. Noise removal helps to detect crack more accurately. Image luminous level is increased and image is converted to binary image. This helps system to detect only crack and helps to remove other unwanted objects. Image once converted to binary image, holes are filled by using image processing method this helps to reject all smaller objects which are not required for crack detection. Intensity value is used for accuracy purpose. Blob analysis method is used to detect large blobs. System detects crack based on number of connected components. System detects crack based on number of blobs involved and mentions whether crack exist or not. Using bounding box functionality, system displays rectangular box around the blob. This system used during railway track inspection. The proposed system is able to detect deeper cracks with 80% success rate and minor cracks with 50-60% accuracy

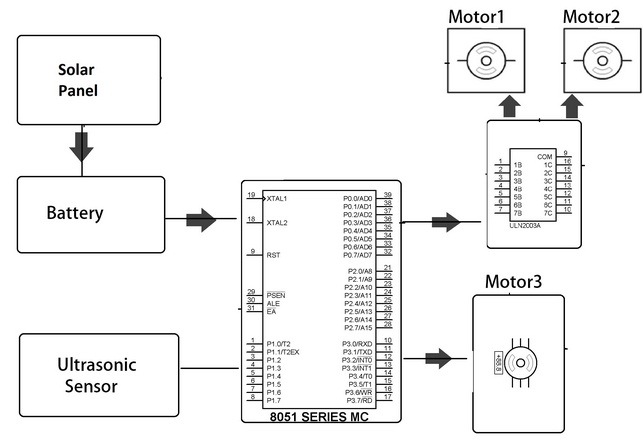

Ultrasonic detection is the method used. When the vehicle detects a crack, it sends a signal to the control room. While it is on the track, the device does not hinder movement of trains. When a train arrives, the device, which uses a pneumatic system, shrinks. The detector helps view the cracks on the track and its GPS system allows locating the vehicle.

1. Automatic Broken Track Detection Using LED-LDR Assembly

2. Robust Railway Crack Detection Scheme Using Led-Ldr

3. Robust Railway Crack Detection Scheme (RRCDS) Using LED-LDR

4. Automatic Broken Rail Crack Detection Scheme

5. Download – International Journal of Advanced Technology

6. Railway track crack detection robot project

7. Railway track crack identification

8. Crack Detector Robot Using LED-LDR

9. Searches related to led-ldr based railway crack detection scheme

10. robust railway crack detection scheme using led-ldr assembly report

11. robust railway crack detection scheme (rrcds) using led-ldr assembly

12. robust railway crack detection scheme using led ldr assembly ppt

13. railway track crack detection system using microcontroller

14. automatic railway track crack detecting vehicle project pdf

15. railway track crack detection system project report

16. railway crack detection circuit diagram

17. railway crack detection robot

18. railway track crack detection system project ppt

19. railway track crack detection project report

20. automatic railway track crack detecting vehicle ppt

21. robust railway crack detection scheme ppt

22. railway track crack detection system project report

23. railway track crack detection system ppt

24. railway crack detection using led ldr ppt

25. Automatic Railway Track Crack Detection

26. IOT: Railway track crack detection robot USING GSM-GPS

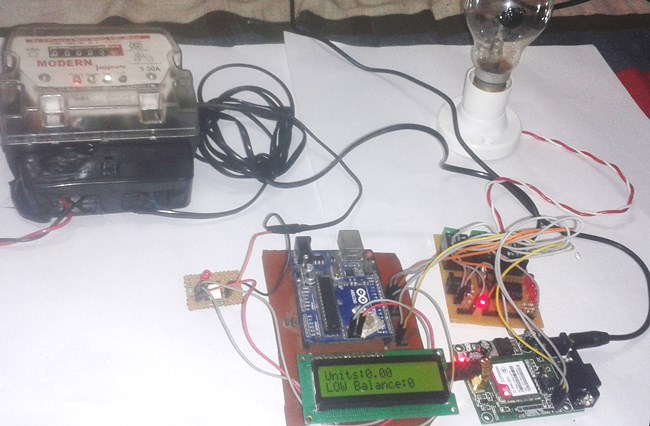

27. IOT: Crack detection Robot For Railway track Inspection

28. Railway track crack detection and SMS alerting System

29. Railway tracks crack detection

30. Crack detection Robot For Railway track Inspection

31. Microcontroller based Railway Crack Detection

32. Solar powered railway track crack detection using GSM GPS

33. Railway track crack detection and SMS alerting System

34. Railway track crack detection robot project

35. railway track crack detection autonomous vehicle

36. Robust Railway Crack Detection Scheme Using Led-Ldr

37. CRACK DETECTION SYSTEM FOR RAILWAY TRACK

38. Railway track, crack detection, ARM, GSM, GPS

39. Automatic detection of squats in railway track

40. IOT: Railway track crack detection robot USING GSM-GPS

41. Robust Railway Track Crack Detection Scheme

42. Railway track crack detection robot project

43. A Modern Method for Detecting Cracks In Railway Tracks

44. automated visual inspection of detecting cracks and obstacles on rail

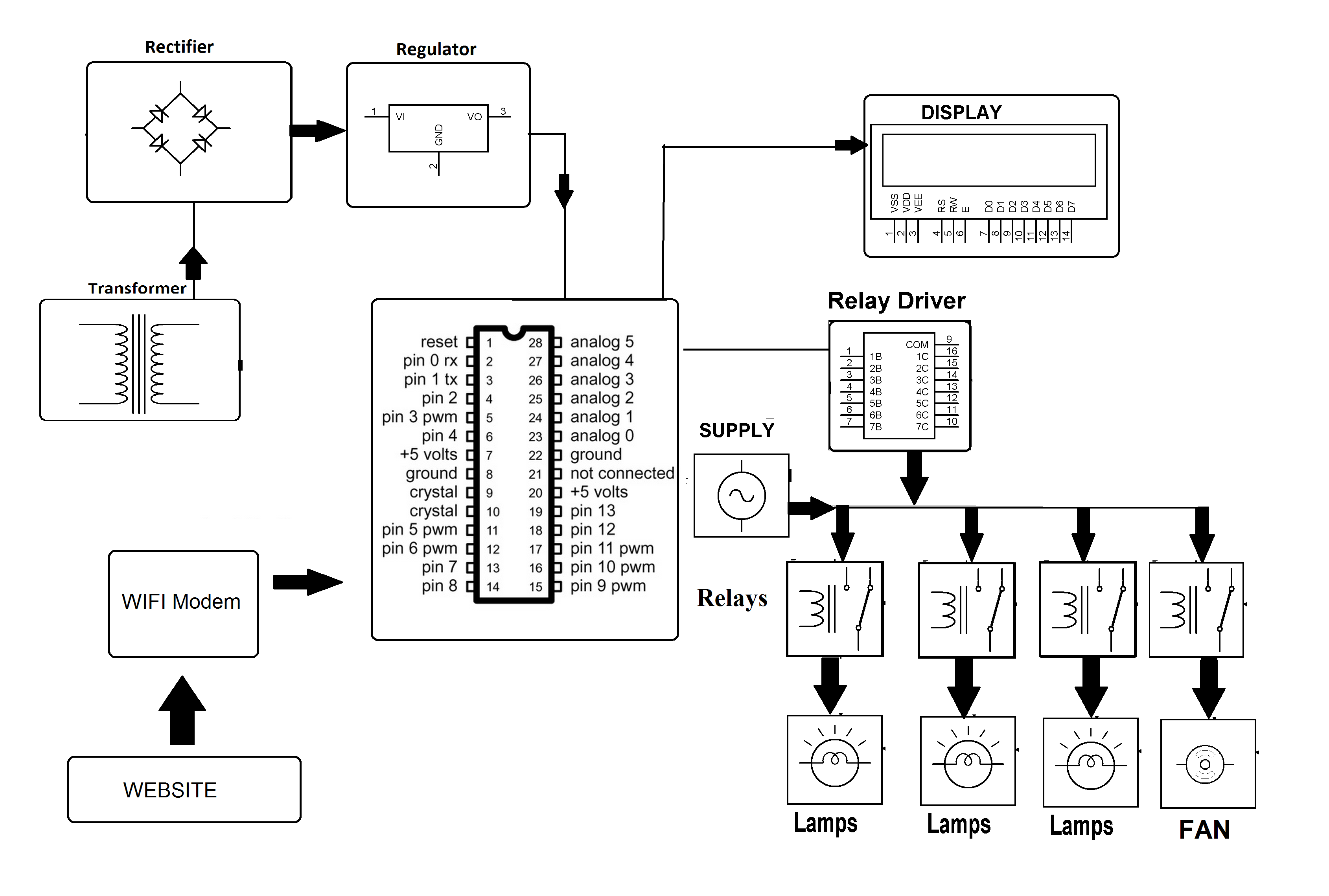

45. 30+ Awesome Internet of Things Project Ideas | mbed

46. crack detection and collision avoidance in railway using arm

47. Automatic Broken Track Detection Using IR Transmitter

48. automatic identification of obstacles and crack sensing scheme in rail

49. AUTOMATIC RAILWAY TRACK FAULT IDENTIFIER

50. Innovative Railway Track Surveying with Sensors

51. 40+ GSM Based Projects for Engineering Students – Electronics

52. A Wireless Approach with Sensor Network for Real Time

53. Solar powered railway track crack detection using GSM GPS

54. A New Novel Control Algorithm/Scheme To Detect Cracks/Damages

55. intelligent railway crack inspection robot

56. Robust Railway Crack Detection Scheme Using ARM IRTRDS Algorithm

57. a microcontroller based stout robot with automatic crack detection

58. Railway Track Security by GSM With User Programmable

59. innovative railway track surveying with sensors and controlled

60. Robot section:GPSMEMS SensorUltrasonicsensorGSM Train

61. MEMS sensor is used for detect the cracks and breakage of tracks.

62. A Novel Approach Railway Track Damage Detection Robot

63. Gps based railway crack detection

64. A microcontroller based stout robot with automatic crack

detection in railway tracks using led ldr

65. Railway Level Crossing Gate Control & Measurement

66. ROBOT WITH AUTOMATIC CRACK DETECTION IN RAILWAY TRACKS

67. ppt on railway track crack detection robot using gsm gps

68. Latest GSM Based Projects for final year engineering students

69. Get new IOT Projects Ideas & Training, IEEE Internet Of Things (IoT)

70. MONITORING OF CRACK INSPECTION AND MAPPING IN RAILWAY

71. Railway Track Monitoring System using GSM Module

72. SMART ROBOT FOR RAIL TRACK FLAW DETECTION USING NDT

73. Railway Security System based on Wireless Sensor Networks

74. An Intelligent Design to Detect Broken Track for Indian Railway

75. Railway Track Crack Detection And Sms Alerting System

76. Innovative Railway Track Surveying with Sensors

77. Railway Track Crack Detection Videos

78. Crack Found On Rail Track

79. Review of Railway Track Fault Finding System

80. Broken Railway Track Detection Using LED-LDR

81. Railway track, crack detection, ARM, GSM, GPS, Auto matic Rail crack detection, GPRS.

82. Low Cost Rail Crack Inspection System

83. Railway Track Fault Detection Project

84. rail robot: autonomous robot can clean and monitor your railway tracks